Why Cable Management Matters: Managed vs. Held SystemsUpdated 2 months ago

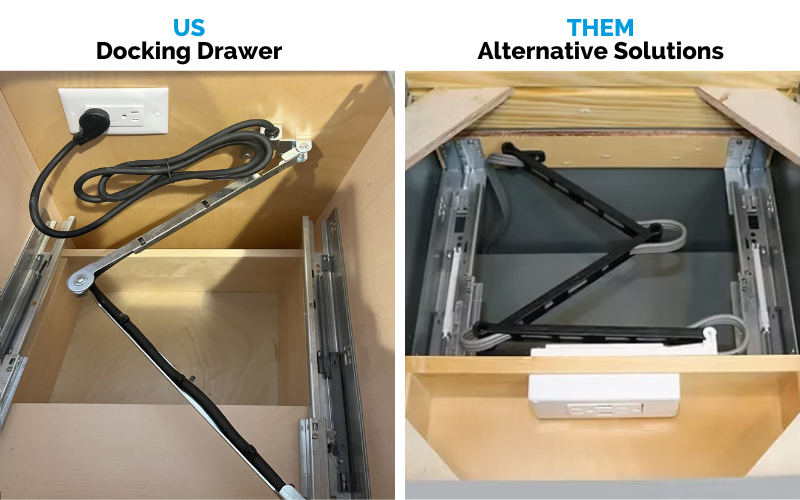

Docking Drawer’s in-drawer outlets prioritize safety and reliability with cable management arms—a critical feature that ensures consistent, long-term performance of the cord that connects the in-drawer outlet to the wall outlet. Unlike competitor products that simply hold in-drawer outlet cables in place, our cable arms actively manage them, reducing risks like cord fatigue and electrical failures.

The Science of Cable Management

Cable management arms control every bend and movement of the power cord, making them the second most important safety feature of in-drawer outlets—only following our patented interlocking thermostat, which de-energizes the outlet if the surrounding temperature exceeds 120°F, preventing potential overheating issues.

Think of bending a paperclip repeatedly until it snaps—this is what happens to unmanaged cables over time. Our arms eliminate this risk by enforcing controlled motion, ensuring cables bend predictably and evenly. This approach mirrors the semiconductor manufacturing principles of our past, where precision and repeatability are essential.

Key Differences

Alternative solutions use systems that are akin to running cables through a straw, allowing the cable to shift freely inside the mechanism. This setup can lead to a single stress point in the cable that weakens over time, creating a failure risk. Without structured cable management, there is a real risk of electrical shorts and premature wear. Our cable management arms are cycle tested to the equivalent of opening and closing a drawer every 15 minutes for over 30 years–compare that with alternative solutions that often lack product cycle testing data, if they test durability at all.

Safety Through Engineering

Our cable management arms are designed to eliminate risk factors:

Strain reliefs prevent mechanical stress from damaging electrical terminations.

Stranded cables flex without breaking, paired with extensive cycle testing (500,000 cycles vs. the industry standard of 25,000) to ensure longevity.

Physical inspections are conducted every 100,000 cycles to monitor wear and compliance.

Docking Drawer (Managed) | Competitors (Held) |

Controlled movement | Free-floating cables |

Predictable stress distribution | Single stress points |

500,000-cycle testing | Unverified durability |

Scientifically designed | Passively retained |

Certifications and Compliance

All Docking Drawer products meet ETL, CSA, CE, and RCM standards, featuring code-compliant designs for high-voltage safety. These certifications provide peace of mind, ensuring that Docking Drawer products adhere to the highest safety and performance standards.

Why It Matters

Managed cables mean safer homes. Whether in a family home, a workplace, or commercial setting, this translates to greater reliability, safety and peace of mind. By choosing Docking Drawer, you invest in a scientifically backed, rigorously tested solution designed for long-term safety. Competitors’ “held” systems gamble on untested durability while our engineered arms turn cable management into a science, not a guess. In short, managed cables = controlled safety.